Plexiglass, also known as acrylic glass, is a popular material for various DIY projects due to its durability and versatility. However, drilling plexiglass can be a challenging task as it tends to crack easily if not done correctly. Cracks can ruin the appearance of the material and even lead to breakage. Fortunately, with a few easy tips, it is possible to drill plexiglass without cracking.

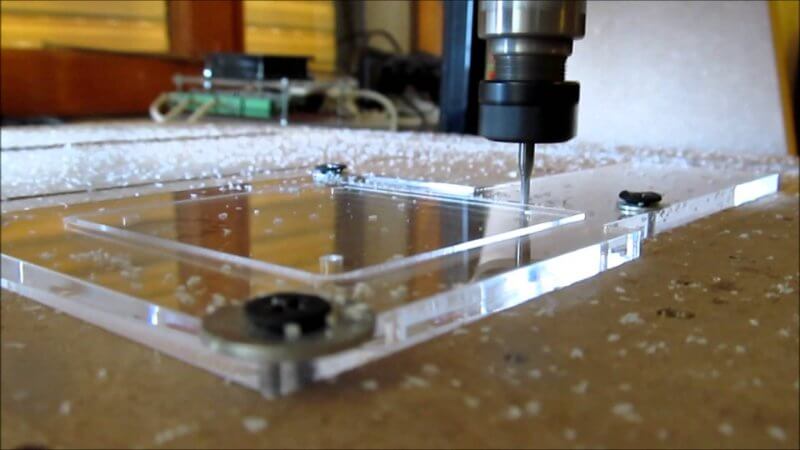

One of the most important things to keep in mind when drilling plexiglass is to use the right tools. Using the wrong tools or using them incorrectly can cause cracks or chips in the material. It is recommended to use a drill bit specifically designed for plexiglass, which has a sharper point and a more gradual angle than regular drill bits. Additionally, using a drill press instead of a handheld drill can provide more control and reduce the risk of cracking.

Another tip to avoid cracking plexiglass while drilling is to use a lubricant. Applying a small amount of lubricant, such as water or oil, to the drill bit and the surface of the plexiglass can help reduce friction and heat, which are common causes of cracking. It is important to avoid using too much lubricant as it can cause the material to become slippery and difficult to handle.

Understanding Plexiglass

Properties of Plexiglass

Plexiglass is a transparent thermoplastic material that is widely used in various applications due to its excellent optical clarity and durability. It is also known as acrylic glass or PMMA (polymethyl methacrylate). Plexiglass has several properties that make it a popular choice for different industries.

- Lightweight: Plexiglass is a lightweight material, which makes it easy to handle and transport.

- Impact-resistant: It is highly resistant to impact and can withstand a significant amount of force without cracking or breaking.

- UV-resistant: Plexiglass is resistant to UV radiation, which makes it ideal for outdoor applications.

- Transparent: It has excellent optical clarity, which makes it a popular choice for display cases, aquariums, and other applications where transparency is essential.

- Easy to fabricate: Plexiglass is easy to cut, drill, and shape, which makes it a versatile material for different applications.

Reasons for Cracking

Although plexiglass is a durable material, it can crack under certain conditions. Here are some of the reasons why plexiglass may crack:

- Stress concentration: Plexiglass can crack if there is a stress concentration in the material. This can occur if the material is not properly supported or if there is a sudden change in temperature or pressure.

- Incorrect drilling technique: If the drill bit is not sharp enough or if the drilling speed is too high, it can cause the plexiglass to crack.

- Incorrect placement of drill holes: If the drill holes are too close to the edge of the plexiglass, it can cause the material to crack.

- Temperature changes: Plexiglass can expand or contract due to temperature changes, which can cause stress and eventually lead to cracking.

To avoid cracking when drilling plexiglass, it is essential to use the correct drilling technique and to properly support the material.

Preparation for Drilling

Before drilling plexiglass, it is important to properly prepare the material to avoid cracking or damaging it. This section will cover the two main preparation steps: selecting the proper drill bit and marking the drill points.

Selecting the Proper Drill Bit

Choosing the right drill bit is crucial when it comes to drilling plexiglass. A standard twist drill bit may cause the material to crack or shatter due to the high speed and pressure. It is recommended to use a drill bit specifically designed for drilling plexiglass, such as a brad point drill bit or a step drill bit.

Brad point drill bits have a sharp center point that helps to prevent the bit from wandering and a sharp outer rim that cuts cleanly through the material. Step drill bits have a cone-shaped tip that gradually widens as it drills, which reduces the risk of cracking.

Before drilling, make sure the drill bit is sharp and clean. A dull or dirty drill bit can cause the material to heat up and melt, leading to a rough or uneven hole.

Marking the Drill Points

Once the proper drill bit has been selected, the next step is to mark the drill points on the plexiglass. This will help to ensure accurate and precise drilling.

To mark the drill points, use a fine-tip permanent marker or a piece of masking tape. Place the tape or marker on the surface of the plexiglass where the hole is desired, and use a ruler or measuring tape to ensure the placement is accurate.

It is important to avoid applying too much pressure when marking the drill points, as this can cause the material to crack or scratch. A light touch is all that is needed to create a visible mark.

By following these simple preparation steps, drilling plexiglass can be a smooth and stress-free process.

Drilling Techniques

Starting with a Small Pilot Hole

When drilling plexiglass, it’s important to start with a small pilot hole. This will help prevent cracking and ensure a clean and accurate hole. A pilot hole should be about 1/8 inch in diameter, and can be made with a standard twist drill bit.

Applying Proper Pressure

One of the most common causes of cracking when drilling plexiglass is applying too much pressure. To avoid this, it’s important to use a light touch when drilling. The drill should be allowed to do the work, without forcing it. This will help prevent the plexiglass from cracking and ensure a smooth and clean hole.

Using the Peck Drilling Method

The peck drilling method is a technique that can be used to prevent cracking when drilling plexiglass. This method involves drilling a short distance into the material, then retracting the drill bit and clearing the chips. This process is repeated until the desired depth is reached. By drilling in short increments, the heat generated by the drill bit is reduced, which can help prevent cracking.

Overall, by using these simple techniques, it is possible to drill plexiglass without cracking. By starting with a small pilot hole, applying proper pressure, and using the peck drilling method, you can achieve clean and accurate holes in plexiglass with minimal risk of cracking.

Temperature and Environment Control

Maintaining Optimal Temperature

When drilling plexiglass, maintaining an optimal temperature is crucial in preventing cracks. Plexiglass has a low melting point and can easily warp or crack when exposed to high temperatures. Therefore, it is important to keep the temperature of the plexiglass and the drill bit low during the drilling process.

To maintain optimal temperature, the plexiglass should be kept cool with a water-based lubricant or coolant. This will help to reduce friction and heat generated during the drilling process. It is recommended to use a spray bottle to apply the coolant to the plexiglass and the drill bit.

Reducing Friction and Heat

Reducing friction and heat is also important in preventing cracks when drilling plexiglass. Friction generates heat, which can cause the plexiglass to soften and crack. To reduce friction and heat, it is important to use a sharp drill bit and to drill at a low speed.

Using a dull drill bit or drilling at a high speed can generate excess heat and cause the plexiglass to crack. It is also important to use a drill bit specifically designed for drilling plexiglass, as this will help to reduce the likelihood of cracks.

In addition to using a sharp drill bit and drilling at a low speed, it is recommended to periodically stop drilling and allow the plexiglass to cool down. This will help to prevent the plexiglass from overheating and cracking.

By maintaining optimal temperature and reducing friction and heat, it is possible to drill plexiglass without cracking.

After Drilling Care

After drilling plexiglass, it is important to take proper care of it to avoid any damage or cracking. Here are some tips to follow:

Deburring the Edges

After drilling, the edges of the plexiglass may be sharp or rough. To ensure a smooth finish, it is important to deburr the edges. This can be done using a deburring tool or sandpaper. Simply run the tool or sandpaper along the edges until they are smooth.

Cleaning the Plexiglass

After drilling and deburring, it is important to clean the plexiglass to remove any debris or dust. This can be done using a soft cloth and a mild soap solution. Avoid using harsh chemicals or abrasive materials as they can scratch or damage the plexiglass.

Once the plexiglass is clean and dry, it is ready to be used for its intended purpose. By following these simple steps, you can ensure that your plexiglass remains in good condition and does not crack or break.